Polymaker ABS Light Blue

Pros/Cons-

Pros:

-Ridgid

-Several colors

-Fairly easy to print with as long as you have the prerequisites

-Reasonable cost

-Multiple Spool size options

Cons:

-Can only order them online

-Will need to make sure you have an enclosed printer that can reach the right temps and maintain it in an enclosure

-Weakness to acetone

Review-

Before I get too far, I want to set something straight. I do not have an engineering degree or have a lot of experience with more engineering grade materials, but I am working on getting more experience and plan on sharing my experiences with you. The Polymaker ABS is the first time I have worked with ABS beyond premade ABS parts. I was contracted for making molds for a friend of mine for candle making and quickly started some research to find a material that has a glass point above 180F and is efficient to print with. I found ABS as a material that should be fairly easy to print with(provided you have an enclosed printer that can reach the correct temps) and match my end temperature requirements. After confirming with a colleague and finding the color my client wanted to continue with, we were off to the races.

After designing and confirming fit with PLA and PETG, it was time to put ABS to the test. I put my files into Bambu Studio with the preset for the Polymaker ABS that was already in the suite, added tree supports and clicked print. It was a cold morning and I had several windows fully open in the room which did cause the base of the print to warp off the plate a little bit, but the rest went off without a hitch. After the print completed, I had a solid print that should have no issues being used as a candle mold. The next time I printed, I had the windows closed significantly more and the warping was significantly reduced. Present, but reduced. Overall, my client seems to be happy with the finished product and excited to put the molds to good use.

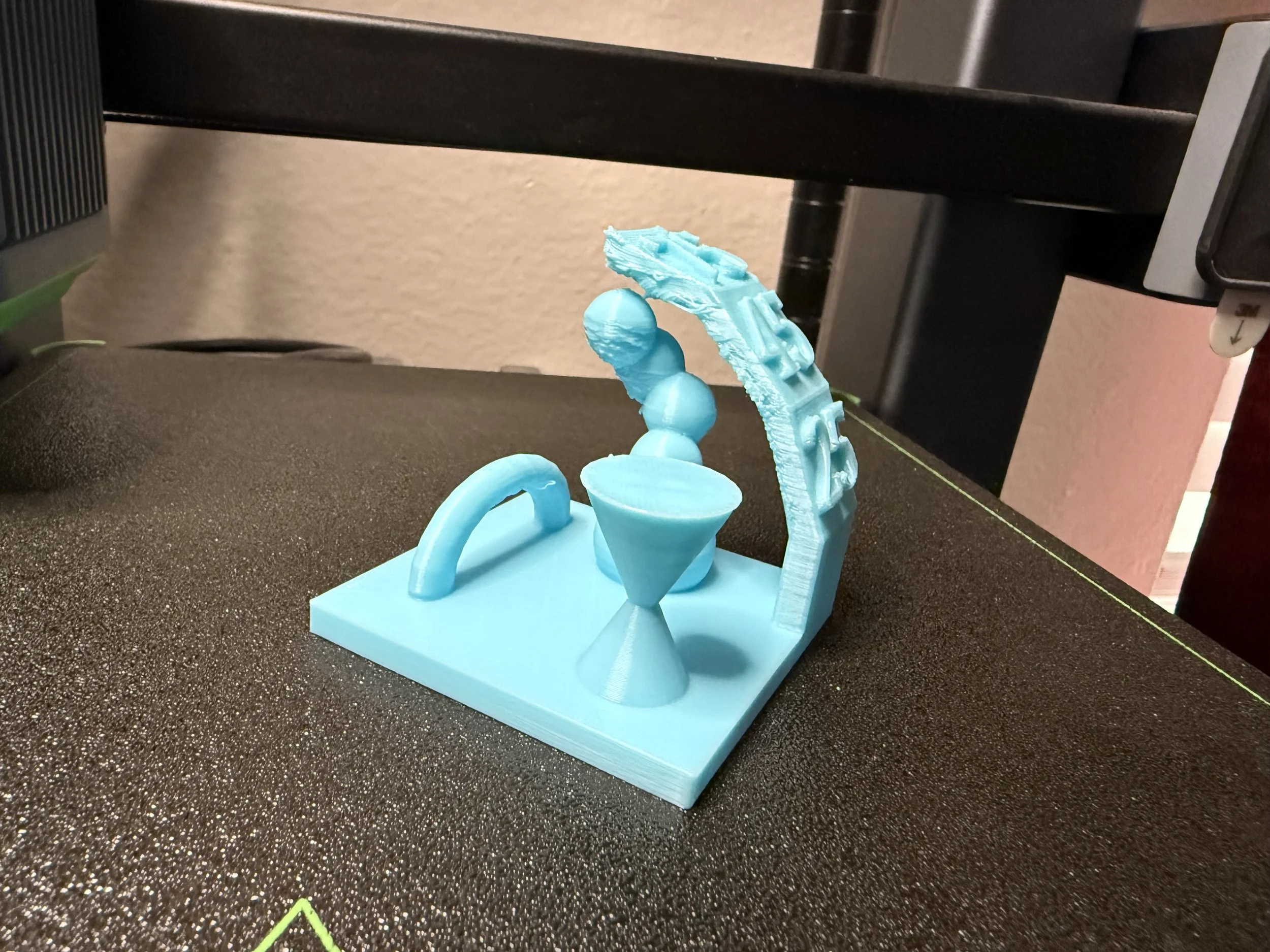

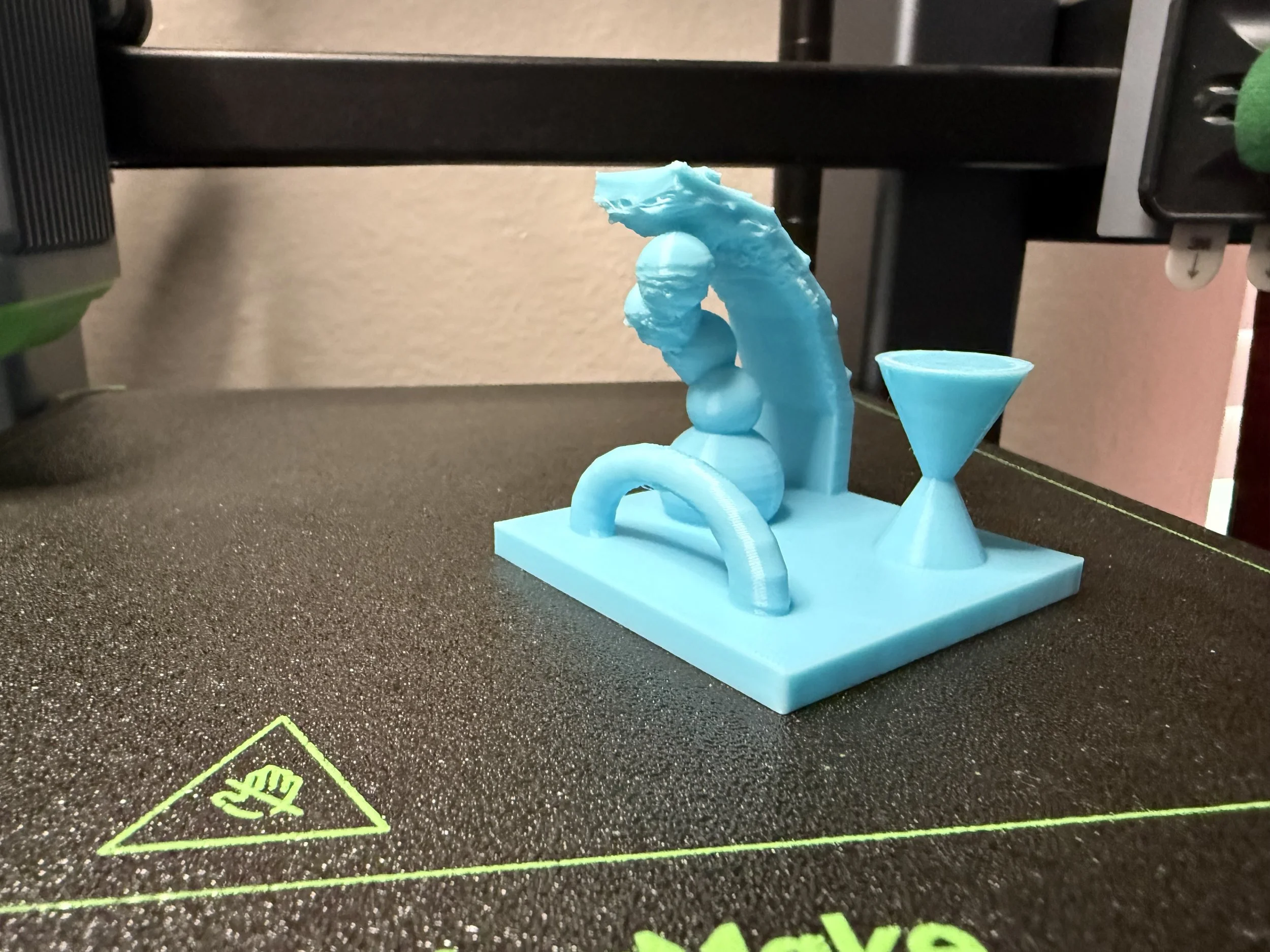

Next came the real tests. In my standard bench mark tests, the ABS did ok, but not great. Everywhere that is solid with no overhang, I got a great finish with no real issues to speak of aside from some warping on the cube. But the overhangs, oh the overhangs. Thankfully it did not do so bad that it tanked the print, but it definitely needs supports in order to really make the overhangs look good. As you can see in the extreme overhang test and the benchy, any time it’s needed to do more than about 30 degrees, it really needs support or you can come out with something that even post processing could have trouble fixing.

Overall, I would say the Polymaker ABS has been fairly easy to work with, but you will want to consider the following when you decide you want to print with it. Can your printer match the higher heat that the filament requires to print? Are you using a hardened metal tip? Are you using an enclosure that can retain heat well? Does your print have overhangs that you are ready to use supports for? If you can answer yes to these questions, you will have a great looking, strong part that really only has a weakness to acetone. If no, you may want to consider a different filament or a different strategy for your print.

Files Used:

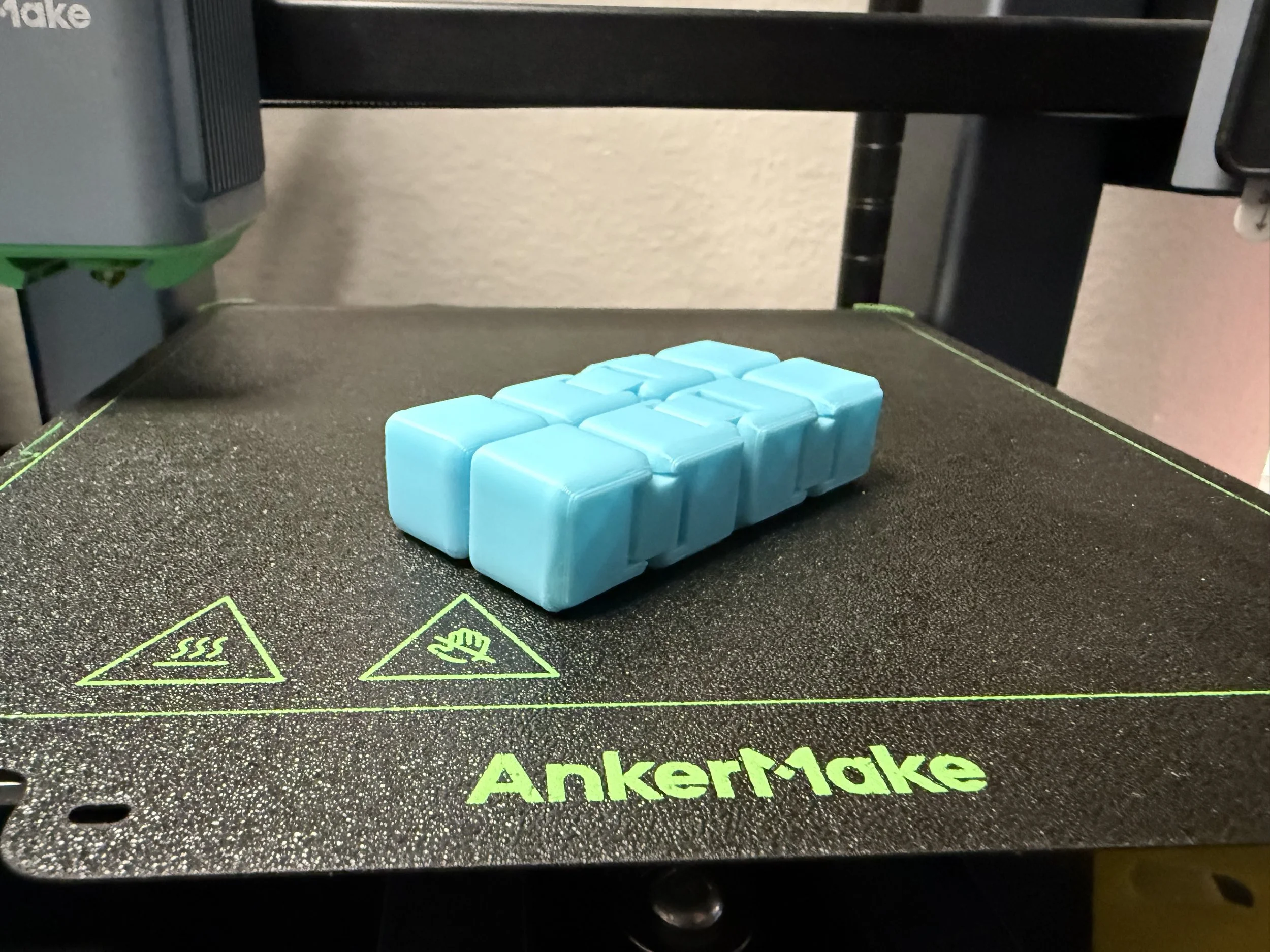

Yet Another Fidget Infinity Cube v2

Buy: